Whether you want to take an idea from concept to prototype or move a design into full production, injection molding is a suitable manufacturing solution. Below, we provide an overview of injection molding, outlining what it is, how the process works, and what to consider when planning an injection molding project.

Injection molding is a manufacturing process that involves the injection of molten materials into preformed molds. It is used to create parts and products in a wide range of shapes and sizes in low and high volumes.

Injection molding is a manufacturing process that involves the injection of molten materials into preformed molds. It is used to create parts and products in a wide range of shapes and sizes in low and high volumes.

There are many injection molding variations, each of which requires the heating and melting of material, injection of the molten material into a mold, and cooling of the material within the mold to form the desired component. Three of the main methods utilized differ based on the material used:

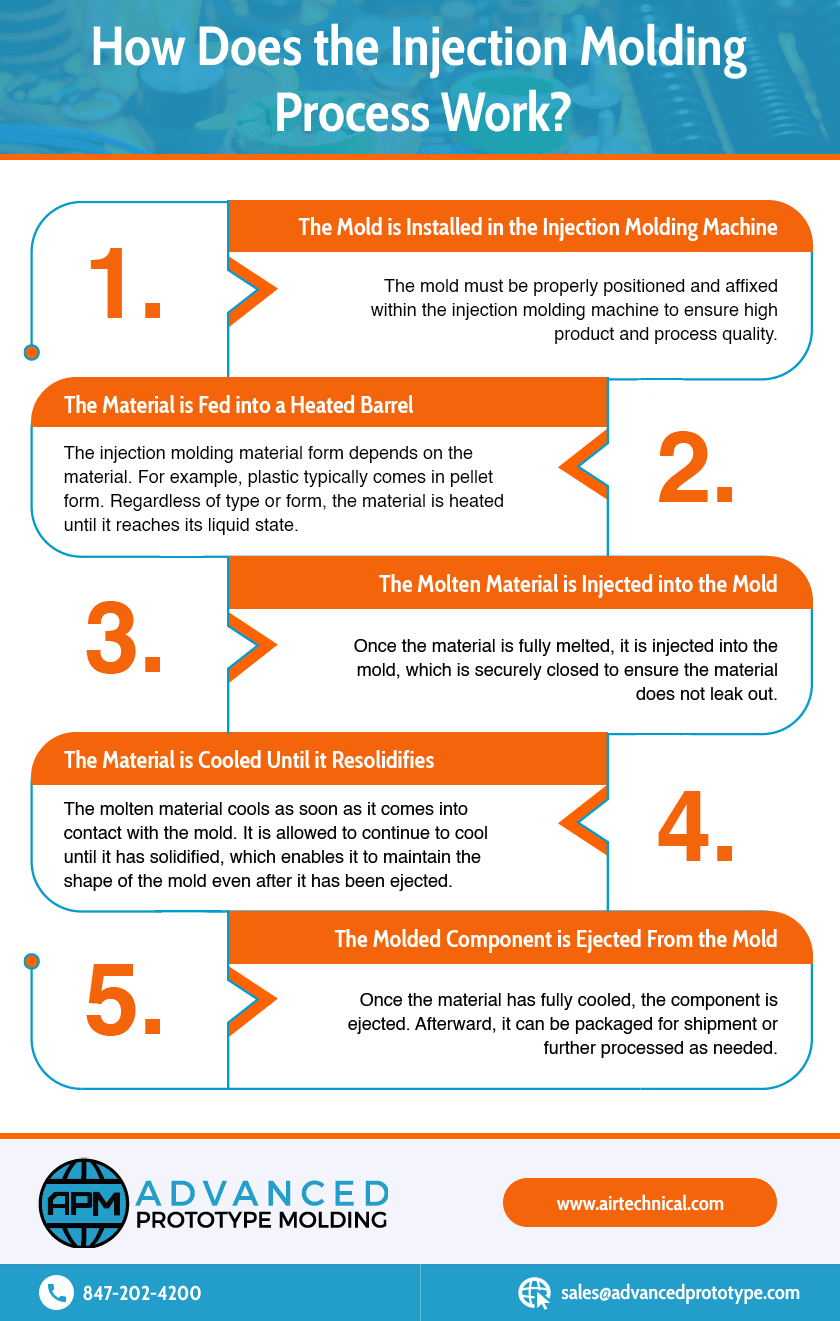

While the injection molding process may vary from project to project, depending on the part and production specifications, it typically consists of the following steps:

While the injection molding process may vary from project to project, depending on the part and production specifications, it typically consists of the following steps:

While there are standard molds available for injection molding operations, many projects require custom molds. These customized components must be designed and built to suit the desired product. Once the molds have been sourced or created, the injection molding process can begin.

Click to Enlarge

The mold must be properly positioned and affixed within the injection molding machine to ensure high product and process quality.

The injection molding material form depends on the material. For example, plastic typically comes in pellet form. Regardless of type or form, the material is heated until it reaches its liquid state.

Once the material is fully melted, it is injected into the mold, which is securely closed to ensure the material does not leak out.

The molten material cools as soon as it comes into contact with the mold. It is allowed to continue to cool until it has solidified, which enables it to maintain the shape of the mold even after it has been ejected.

Once the material has fully cooled, the component is ejected. Afterward, it can be packaged for shipment or further processed as needed.

There are many factors to consider when planning an injection molding project. Some of the questions you should answer before beginning the project include:

If you’re outsourcing your prototyping and/or production operations, the injection molding company you partner with should be able to meet all of your requirements and restrictions.

Looking for an injection molding company that is as committed to your project success as you are? Advanced Prototype Molding is the ideal partner!

At Advanced Prototype Molding, we are a full-service injection molding company. We provide design, mold engineering, injection molding, assembly, finishing, and many other related services all under one roof, which enables us to turn our customers’ concepts into reality while saving them time and money.

To learn more about our injection molding capabilities, check out our injection molding services page or contact us today. To partner with us on your next injection molding project, request a quote.

ADVANCED PROTOTYPE MOLDING

1520 N Old Rand Road Wauconda, IL 60084

Tel: 847-202-4200

Fax: 847-202-4270

sales@advancedprototype.com

ADVANCED PROTOTYPE MOLDING

1520 N Old Rand Road Wauconda, IL 60084

Tel: 847-202-4200

Fax: 847-202-4270

sales@advancedprototype.com