In the world of manufacturing, prototypes are commonly used in both the design and development of physical objects, particularly when large system building construction or manufacturing is involved. Advanced Prototype Molding has over 40 years of experience in building reliable, high-quality prototypes. Here, we will discuss the importance of product prototyping as well as its processes, materials, and benefits.

Prototyping is a process in which a sample product is created that can then be tested in a “real world” environment similar to the one the final product will be used in. It gives you a chance to test quality and identify issues in a relatively low-stakes environment before mass production begins. A prototype serves as a "throwaway" model that is made to understand the requirements of a project prior to the design and coding phases.

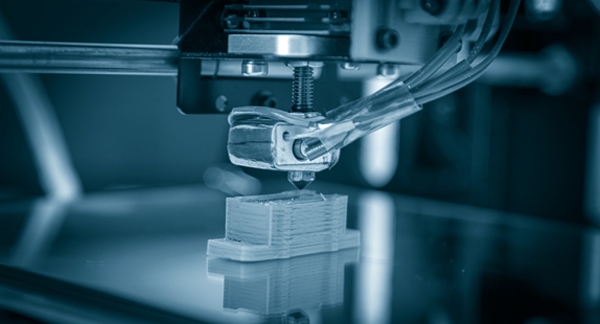

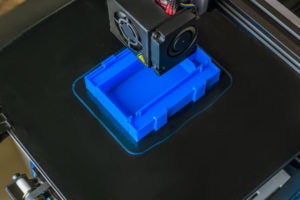

Rapid prototyping is an accelerated version of prototyping that employs both 3D CAD software and 3D printing technology. With a rapid prototype, customized products no longer need to be created from scratch - thus improving product development significantly.

For projects that require revision and end-user feedback, prototyping is a must. It's far easier and less expensive to implement significant changes on a prototype than it is once a product has entered full-scale production. By creating a prototype, you can actually physically interact with a proposed product and see which elements of it are working and, more importantly, which ones need refining.

There are various prototype manufacturing processes to choose from depending on your needs. These include:

At Advanced Prototype Molding, we offer these product prototyping methods with a wide range of material options, including:

Plastics:

Rubber:

Metals:

Misc:

Advanced Prototype Molding can help you select the best prototyping method and materials for your specific application.

Prototype manufacturing brings with it a wide range of benefits. One of its main advantages is its ability to reduce time and costs. Prototyping allows you to address small problems now before they have a chance to become much bigger ones later on in the manufacturing process, thus increasing the speed at which you're able to get your products to market.

Not only that, but the prototyping process allows you to better test product features, manufacturing methods, user experiences, and more before you enter full-scale production. Product prototyping also leads to better visualization of the final product as well as improved and increased user involvement.

Product prototyping offers a host of advantages that make it an extremely important manufacturing process for various industries. By being able to test and visualize the product, you can make the necessary adjustments and improvements before final production, saving both time and money.

At Advanced Prototype Molding, we offer a broad selection of rapid prototyping and 3D printing services for various industries, including:

If you'd like to find out more information about the benefits of product prototyping, or for more information about our services, please contact Advanced Prototype Molding today. You can also fill out a request for quote to get started on your next rapid prototyping project.

ADVANCED PROTOTYPE MOLDING

1520 N Old Rand Road Wauconda, IL 60084

Tel: 847-202-4200

Fax: 847-202-4270

sales@advancedprototype.com

ADVANCED PROTOTYPE MOLDING

1520 N Old Rand Road Wauconda, IL 60084

Tel: 847-202-4200

Fax: 847-202-4270

sales@advancedprototype.com