Manufacturers use molding processes to create high-volume orders of precision components, prototypes, and everything in between. There are multiple different types of molding processes available, with blow molding and injection molding being popular options. Both can create high-quality parts that meet tight tolerances and budget requirements. However, there are key differences between the two processes that are important to understand before selecting the right fit for your next production order.

Click to Enlarge

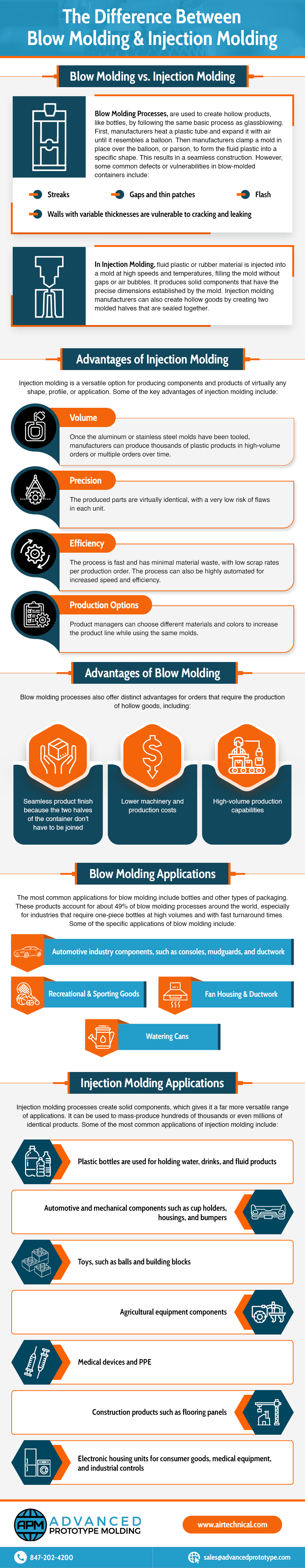

Ultimately, blow molding and injection molding are used to create different types of products. In injection molding, fluid plastic or rubber material is injected into a mold at high speeds and temperatures, filling the mold without gaps or air bubbles. It produces solid components that have the precise dimensions established by the mold. Injection molding manufacturers can also create hollow goods by creating two molded halves that are sealed together.

Blow molding processes, on the other hand, are used to create hollow products, like bottles, by following the same basic process as glassblowing. First, manufacturers heat a plastic tube and expand it with air until it resembles a balloon. Then manufacturers clamp a mold in place over the balloon, or parson, to form the fluid plastic into a specific shape. This results in a seamless construction. However, some common defects or vulnerabilities in blow-molded containers include:

While both processes are cost-effective and reliable, the type of product you want to produce is the main deciding factor in which process you should select.

Injection molding is a versatile option for producing components and products of virtually any shape, profile, or application. Some of the key advantages of injection molding include:

Blow molding processes also offer distinct advantages for orders that require the production of hollow goods, including:

Both blow molding and injection molding can quickly and efficiently produce plastic goods. But injection molding is commonly used to create solid plastic parts and products with a filled interior, and blow molding creates seamless, hollow parts, such as bottles and hollow toys. Because the two processes produce different types of plastic goods, the applications for each method differ.

The most common applications for blow molding include bottles and other types of packaging. These products account for about 49% of blow molding processes around the world, especially for industries that require one-piece bottles at high volumes and with fast turnaround times. Some of the specific applications of blow molding include:

Injection molding processes create solid components, which gives it a far more versatile range of applications. It can be used to mass-produce hundreds of thousands or even millions of identical products. Some of the most common applications of injection molding include:

Both injection molding and blow molding processes are popularly used throughout multiple different industries. At Advanced Prototype Molding, we're a leading provider of high-quality plastic molding, mold fabrication, plastic finishing services, and more. Contact us today to learn more about our capabilities or request a quote for pricing details.

ADVANCED PROTOTYPE MOLDING

1520 N Old Rand Road Wauconda, IL 60084

Tel: 847-202-4200

Fax: 847-202-4270

sales@advancedprototype.com

ADVANCED PROTOTYPE MOLDING

1520 N Old Rand Road Wauconda, IL 60084

Tel: 847-202-4200

Fax: 847-202-4270

sales@advancedprototype.com