Prototyping used to be an expensive and time-consuming process in engineering, but fortunately, recent technological developments in 3D printing have changed that. Although 3D printing technology has been around for more than 30 years, it’s only recently become an economic choice for mass production.

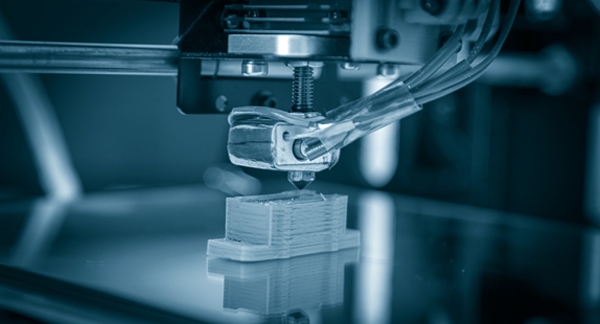

3D printing and rapid prototyping may seem like similar processes, but a few crucial differences exist between them. 3D printers manufacture items by turning digital 3D models into objects. Unlike subtractive processes like CNC, 3D printing builds objects by adding material from a print head, nozzle, and other methods, allowing to precisely control the number of resources spent on prototyping. To put it another way, 3D printers can create something out of nothing.

Rapid prototyping is also an additive process, but it uses special materials such as photopolymers, thermoplastics, and metals to fabricate objects much faster than traditional prototyping methods. There are four major types of rapid prototyping, which we discuss below.

3D prototypes allow manufacturers to test new ideas and gauge performance before sending parts to mass production. Prototyping offers the flexibility to create multiple models, allowing you to experiment with a number of different builds at once. Because 3D-printed prototypes work for both visual and functional testing, they’re wildly popular among manufacturers who are testing new ideas.

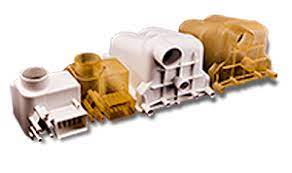

Understanding the different types of rapid prototyping will help you decide the best process for your needs. Manufacturers rely on four main types of prototyping:

Each of these processes uses a versatile range of materials. PolyJet and SLA processes operate with all kinds of photopolymers, FDM uses thermoplastics such as nylon and acrylonitrile styrene acrylate, and DMLS works with metals ranging from aluminum to titanium.

Advanced Prototype Molding will work with you to determine the best 3D-printed prototyping process for your needs. We’re experts in the industry, and we can’t wait to see what we’ll work on next.

For more information on 3D printing, rapid prototyping, and how you can use these processes to make the most of your product testing, contact us, and request a quote today.

ADVANCED PROTOTYPE MOLDING

1520 N Old Rand Road Wauconda, IL 60084

Tel: 847-202-4200

Fax: 847-202-4270

sales@advancedprototype.com

ADVANCED PROTOTYPE MOLDING

1520 N Old Rand Road Wauconda, IL 60084

Tel: 847-202-4200

Fax: 847-202-4270

sales@advancedprototype.com